Articles

Your one stop shop for all your health & safety resources

Successfully Managing Heat Stress Prevention Programs

With outside temperatures starting to increase in many parts of the world, it may be the time to ensure employers are taking those important steps to protect workers from heat stress and heat-related illnesses. Heat can cause more than just discomfort, exposure to such environments can be life-threatening unless strong measures are in place to manage an organization’s work activities during these periods.

If you are working in parts of North America, South America, Far Asia, Africa, Australia or the Middle East you are likely to go through those uncomfortable times of year where heat stress begins to become a real issue affecting workers.

During these hot summer months, working temperatures may even rise to reach heights of 40º to 55º degrees Celsius, with the humidity levels also adding to the severity of the situation. In many organizations faced with such issues, heat stress immediately becomes the number one workplace hazard, not only due to the effects of temperature on the human body but also as a result of the secondary impact such temperatures may have.

Extreme temperature can have serious effects on working process such as machinery or chemical plants as well as creating an environment for employees to take shortcuts, or causing them to make important workplace decisions when they are agitated or lightheaded as a result of the heat. A secondary impact which can place themselves or their colleagues at considerable risk.

Working in the middle east for the last few years I have been involved in developing a number of successful heat prevention programs with a number of organizations in various industries. I also have to add, I have been involved in a few not so successful programs as well, ones in which we ended up eating up much-needed resources with no obvious benefits or overall injury reduction.

I have used this article to highlight some of the essentials that make the basis of any successful heat prevention program

Plan the work with heat stress in mind.

Employers must recognise the hazards associated with heat stress. Health and safety professionals should always be present to provide valuable input regarding the controls required for the various types of workplace activities. In general, every effort needs to be made to minimise the amount of work during the times of extreme heat

Heat stress potential should always be considered in the planning stages of any projects such as turnarounds or construction activities. Considerations to the hours of work must be made with potential shift changes from day to night to avoid the hotter hours of the day.

Plans to control heat stress must also be integrated within the various site documentation such as Risk Assessments, Job Safety Assessments (JSA) or Permit to Work Systems. Precautions required as a result of these documentations such as establishing rest shelters, rest periods, working in buddy systems or immediately stopping work if the water runs out, must be considered as essential and in the same league as hard control measures such as gas tests, scaffolding rails or work site barriers.

Establish a heat index…. Humidity really matters!

Many organizations use different types of mechanisms to consider how to measure heat stress within their operations. Some would consider assessing the metabolic rate of an individual (rate of internal heat generation) specifically when work activities require an employee to work in extreme temperatures remotely and often unsupervised. And then there are various mechanisms to assess the environmental conditions such as psychrometric wet bulb temperature (Considers evaporate cooling), Ambient water vapor pressure (various considerations for humidity), Natural wet bulb temperature (Considers air flow or airspeed), Globe temperature (Considers radiant heat from nearby processes as well) and a number of others.

Depending on the type of specific work hazard or PPE involved, one or more of the above measuring technique might be required. IF this is the case within your organisation, you may wish to consult an occupational health specialist or an industrial hygienist for a more suitable process.

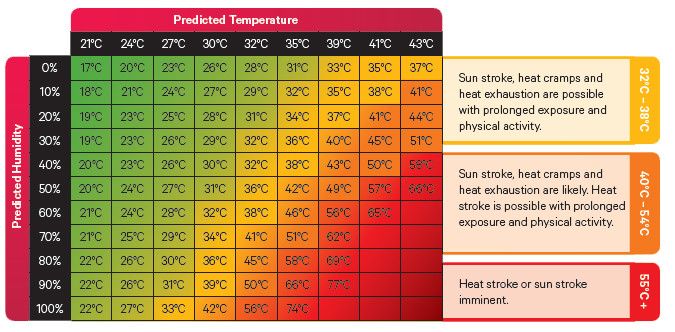

My advice would be to keep it as simple as possible. The majority of organizations I have worked with would use a Wet Bulb Globe Temperature (WBGT) index or a slight variation of it that does not take specific thresholds into consideration and provides a number of heat control strategies such as the below (Courtesy of Keyes to Safety LLC):

Whichever method your organization decides it is important to establish something such as the above in order for employees to understand what actions are required to be taken based on the category. The different colours on the illustrations (Green, Yellow, Orange and Red) are then used to set control measures.

People often ask me if there is a guiding standard for heat indexes, and the answer is…not quite, as it is generally left to organizations to come up with their own based on general weather conditions and operations within their locality, although OSHA (Occupational Safety and Health Association) in the United State provide a guidance’s as to how heat stress should be managed. The Health and Safety Executive of the United Kingdom does not provide such detail although does give a guiding framework of the basic actions to take.

Training and awareness is of the essence

Regardless of the type of industry in which a company operates, setting up an effective training program to deal with heat stress is of the essence.

Independent research has shown that a good heat stress training program on its own can sometimes reduce heat stress injuries in an organization by up to 75%. Such statistics make a lot of sense as employees being aware of what heat stress can cause as well as an understanding the early symptoms can ensure appropriate actions are taken.

Training needs to be effective and where a multilingual workforce is operating, tailored to the different languages.

The below highlights some of the essentials that need to be communicated to a workforce as part of any heat stress training program:

- An understanding of heat-related illnesses (e.g. heat stroke, heat exhaustion, heat cramps, heat syncope and heat rashes), immediate action if early symptoms are noticed and the first aid measures for each.

- Company rules and policies regarding heat stress as well as an explanation of the risk control based on the categories.

- Importance of constantly drinking water, the recommended amount of water per category and the importance of stopping work if water runs out onsite.

- Explaining how certain medications such as antibiotics or cough syrup can cause additional dehydration and could put the person at additional risk.

- Avoiding drinks such as coffee and decaffeinated drinks if they are planning to work in the heat for a long period of time

- Eating meals at regular times provide the nutrients and salts necessary to best work in warm weathers.

- Enforcing the importance of taking regular rest breaks in shaded areas and as a minimum following the break requirements highlighted by the heat category.

- Understanding their current hydration levels from urine colour.

- Understanding the need to acclimatise to adverse temperatures for personnel working in such environment for the first time. Also understanding that this may take at least a two-week period.

- Importance of hygiene and taking showers at the end of a working day to prevent heat rashes

Efforts need to be made to ensure all required personnel are trained prior to the start of the hot summer months.

PPE & Engineering Controls

A number of engineering controls can greatly support worker safety during high temperatures. Safety professionals, as well as organization managers, should very much consider any control which could reduce these risks. Purpose built resting shelters, provision of ventilation and any other body cooling mechanisms could be considered.

With regards to Personal Protective Equipment (PPE), consideration for lighter clothing as well cooling vest for the more critical type of activities may be required.

The temptation not to use PPE will be extremely strong during hot weather periods when planning the work, the need for the PPE must be considered and the importance of wearing it when working consistently reinforced.

Communication

Methods of communicating the changes in temperature to the workforce are needed. These are examples of how this can take place:

- The use of a flag system: a flag is displayed showing the colour of the risk category (Green, yellow, Orange or Red). This will let everyone know the work to break ratio, recommended water intakes and other recommendations the employer may wish to communicate. A certain colour would need to be used to highlight that all work is to be stopped once the heat index becomes very critical throughout the day.

- Where possible, use telecommunication tools such as radios or text messages on mobile phones to send internal communications messages highlighting the heat stress index category.

Many HSE departments initiate various heat stress related safety campaigns prior to the hot weather months starting, this may include posters and banner throughout the organization, companywide communications through email, safety moments during meetings or even toolbox talks prior to starting work.

Supervision

The role of line managers and supervisors are critical during these periods, they must pay particular attention to the performance of their site workers.

They must communicate the hazards on site at the beginning of every work shift, ensure water and cool shaded areas are available for resting, manage work and rest periods, as well as pay attention to any individual workers likely to be more susceptible to heat stress as a result of physical conditions, illness or the lack of acclimatization.

The supervisor also acts as a point of contact for any major emergency situations regarding heat stress. Supervisory first aid training may need to include more elements on dealing with conditions such as heat strokes or heat exhaustion.

Knowledge can mean the difference between life and death when it comes to working in extreme hot weathers. All personnel working within an organisation susceptible to such conditions should understand the nature and symptoms of heat-related illnesses. In many cases, a quick and efficient response can save a heat stress victim from numerous long-term effects.

Proper training, controls and a strong heat stress prevention program will help protect your employees all year round.

Submit form

+ Training

+ Consulting

+ Support Services

+ Professional Development

Let us know which service you are interested in:

Please complete the form below and a member of our team will be in touch within 1-3 business days

Thank you for your interest in Demoura Lawson Consulting

Contact Us

Qatar: Unit Office No. 1905: 19th Floor, The E18hteen Tower , Bldg 230, Street 303, Zone 69, Lusail Marina , Qatar

Tel: +974 4445 9206

Saudi Arabia: 3121 Imam Abdullah Bin Saud Bin Abdulaziz Road, Ishbiliyah, Riyadh 13225, Saudi Arabia

Tel: +966 50 685 6910

ADD A COMMENT

March 13, 2018